If you are a property manager, you know the importance of keeping your property looking its best. One way to execute this is by sealcoating your asphalt surfaces regularly.

Sealcoating helps protect your asphalt from weathering and wear and tear. It can also refine the appearance of your property. However, there are some things that you need to know about sealcoating before you decide whether or not to have it done.

In this blog post, PowerSurge Plus LLC will discuss some of the most critical facts about sealcoating that every property manager should know!

No. 1: Fights Fading

One of the main perks of sealcoating is that it helps protect your asphalt from fading and oxidation. UV rays from the sun, stagnant water, and air pollution can all cause asphalt to fade and become discolored.

Sealcoating helps create a barrier between your asphalt and the elements, which will help keep it looking new for longer. Once applied, it restores the original color of asphalt and gives it a fresh, new appearance.

No. 2: Durable Destiny

Sealcoating asphalt is one of the most cost-effective ways to maintain and prolong its lifespan. By sealcoating, you are essentially giving your asphalt a protective layer that will help prevent damage from weathering, water, oil, and gas leaks.

These advantages make sealcoating one of the best investments a property owner can make. You’ll be able to preserve your asphalt, save money in the long run, and extend its lifespan.

No. 3: Cracked Question

Although sealcoating goes a long way to prevent asphalt cracking, it’s important to note that it cannot and does not fill in cracks that have already formed.

This is where asphalt repair comes in. Asphalt repair is filling in existing cracks to prevent further damage and keep your asphalt looking its best. Cracks can form for various reasons, including weathering, water damage, tree roots, and more.

Sealcoating is a preventative measure that will help you avoid the need for asphalt repair. Still, it’s essential to understand the roles of both asphalt maintenance options.

No. 4: Melting in Minutes

In the colder months, you can expect any ice or snow on your asphalt to melt quickly. That’s because asphalt is dark material, and it absorbs heat from the sun more efficiently than lighter-colored materials.

Sealcoating helps trap this heat beneath the surface of the asphalt, accelerating the melting process and shielding the asphalt from the water penetration and freeze-thaw cycles that can cause cracks and potholes.

The Gist

As you can see, sealcoating is a vital asphalt maintenance step, especially in areas that experience cold winters.

At PowerSurge Plus LLC, we offer reliable sealcoating services in Cherry Hill, NJ. Our mission is to help property managers keep their asphalt in top condition. Don’t hesitate to reach out to us for all your sealcoating needs.

Exploring The Seal Coating Best Practices

If you own or run a business, you know that your property’s exterior is essential. It is the first thing customers see when they arrive, and it has the power to build or destroy their opinion of your business. That is why it is critical to maintaining your property’s appearance.

One way to do this is by seal coating your pavement. It helps protect your pavement from weathering and fading and can also help improve the appearance of your property.

In this blog post, PowerSurge Plus will explore the best practices of seal coating so that you can make an informed decision about whether or not this service is right for you!

Clean and prepare the surface properly:

Ensure the asphalt surface is clean to ensure the seal coat adheres nicely. Dirt, aggregates, stones, oil spills, and grease can all cause the asphalt sealing to fail.

Trim any vegetation bordering the asphalt surface before you begin seal coating. Grass can get stuck in your sealer and cause ugly stains.

Do a thorough assessment for cracks and potholes. Is there any evidence of water leaking through the gaps, such as unexplained water pools or clay streaks? If that’s the case, it’s a sign of inadequate drainage. Coatings will eventually fail in such regions regardless of how often you go back to try to address the situation.

Use the appropriate sealer:

Seal coats come in various forms, including coal tar emulsion, asphalt emulsion, oil-based, fast-drying, and acrylic. Each of these varieties has advantages and disadvantages. When selecting a product to use, keep these points in mind. The coal tar emulsion is the most often utilized because of its durability and price.

Use the right mixture:

Follow the manufacturer’s recommended mix, coverage rate, and coat count. Any variation, such as utilizing a watered-down mix or “black water,” might result in poor outcomes. Before applying the mixture, make sure it’s well mixed. To create a long-lasting impact, choose high-quality materials.

Use two coat process:

Apply the first coat using a squeegee or a broom. This procedure ensures that the sealer substance is correctly applied to the surface.

After the first coat has been thoroughly dried, a second layer can be sprayed.

It’s critical to provide enough time for curing. It’s important to avoid allowing traffic on it in between coatings.

Spraying a second coat helps achieve a smooth and uniform finish that is both aesthetically pleasing and long-lasting.

Stay patient:

In ideal hot and dry circumstances, seal coat materials cure rapidly; nevertheless, colder temperatures and high humidity lengthen drying time. All seal coat projects should be allowed to dry for a minimum of 24-36 hours before allowing traffic back on them or reapplying line striping.

When is the best time to sealcoat?

PowerSurge Plus experts suggest seal coating at least one to two years following the first asphalt treatment. This permits the asphalt to cure correctly and the outermost layer to wear down. Sealcoating should be done every two to three years.

Do you want your parking lot, driveway, or any other commercial or residential property in Philadelphia, PA, to be seal coated by experts who appreciate the value of a well-kept and long-lasting pavement? For a high-quality yet reasonably priced quotation, get a quote today!

There’s nothing as therapeutic as playing a game of tennis on a court with pristine white stripes. Unfortunately, those stripes can start to fade over time, and when that happens, it’s definitely not as pretty to look at. If you’re dealing with faded stripes on your tennis court, don’t worry, PowerSurge Plus LLC gives you six reasons why it might be happening!

1. You Have Used the Court Wholeheartedly

Fading stripes on your tennis court signify that you have used your tennis court wholeheartedly. Friction due to the footwork of your game can cause wear and tear on the surface. As a result, you will see visible signs of fading stripes on your court.

2. The Paint was of Low Quality

Whether you painted the stripes yourself or hired someone else, fading lines can signal low-quality paint. To identify this, recall how long it has been since you have gotten the job done. If it hasn’t been too long, then there’s a strong possibility that a substandard product was used for striping your tennis court.

3. The Surface Was Not Prepared Adequately

Preparation before the striping is one of the essential steps of the process. If you avoid this crucial step, it will cause the paint to fade quickly. The surface needs to be squeaky clean and dry before any painting can occur.

4. You Did Not Hire a Professional

Painting stripes on a tennis court is not an easy DIY task, and yet, some people commit the mistake of taking it upon themselves to get the job done.

A professional company has ample experience carrying out each task with ultra-precision. The reason that your tennis court stripes are fading could be improper methods and techniques used while painting the stripes.

5. Exposure to Elements

Outdoor tennis courts are constantly exposed to the sun and rain. Over time, the heat and excess moisture can cause the paint to fade. If you live in an area with high humidity, it can also affect how long your stripes last.

In areas observing extreme weather, such as Cherry Hill, NJ, where summer is warm and humid and winters cold and snowy, the chances of stripe fading get even higher.

6. It Has Run its Course

Some truths are more brutal to acknowledge. Even if you take care of your court and it’s in a shaded area, there comes a time when the paint starts to fade and chip. Trace back to how long it has been since you last painted the court. If it has been more than a few years, it might be time for a new coat of paint.

If the sight of your tennis court with fading stripes is unbearable to you, we recommend that you hire professionals for a repaint. And what better option in Cherry Hills, NJ, than PowerSurge Plus LLC. We offer a wide variety of services to keep your court looking amazing. Not only do we provide top-grade sport court striping, but we also do sport court surfacing, among other services. Contact us today for a free quote!

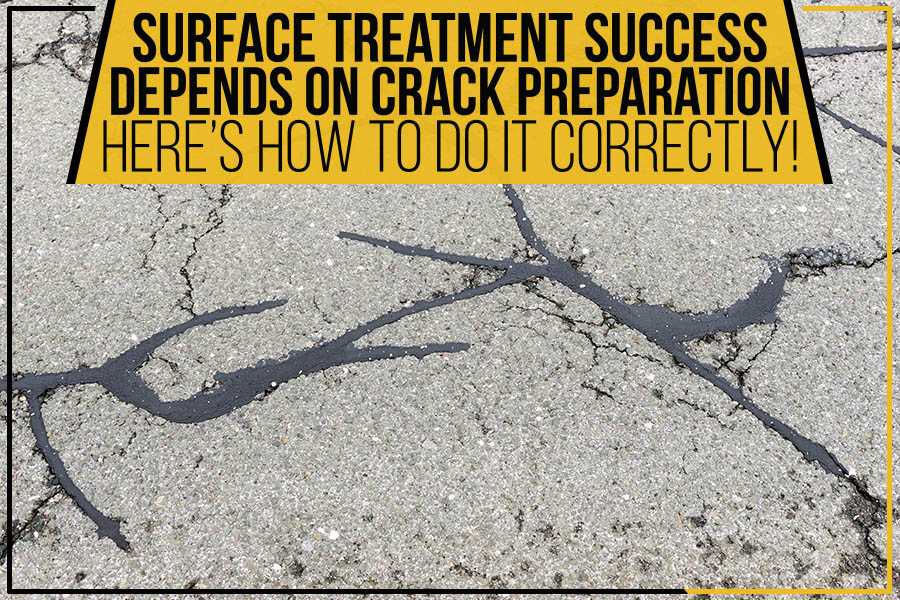

Are you looking for a surface treatment that will last? If so, you need to ensure that the crack preparation is done correctly. Many people mistake not preparing the surface properly, which leads to problems down the road. In this blog post, PowerSurge Plus LLC will discuss how to prepare the surface correctly to get the most out of your surface treatment!

How do cracks affect the surface treatment?

Pavement overlays and preservation treatments are often used to restore surface course qualities such as smoothness, friction, and aesthetics or give structural support to an existing pavement.

However, suppose there is a crack on the existing pavement. In that case, these faults will frequently occur, resulting in premature pavement collapse in the form of cracks and deformations.

To extend the usable life of an overlay, you should hire a professional to fill, rebuild or seal the failing areas of existing pavements.

What to do with cracks?

Crack sealing is often done using liquid asphalt, cutbacks, or emulsions. Crack sealing is perhaps the single most significant maintenance task as this preventative maintenance reduces asphalt degradation; consider a crack to be a scrape on your skin. It becomes infected and spreads if left untreated, causing a much bigger problem.

Where can you do crack sealing?

Crack sealing keeps a securely sealed crack only as long as the pavement is immobile and structurally stable. It is necessary to reseal your surface every year, especially in high-temperature conditions where expansion and contraction occur. Sealing and filling should only be done on dry surfaces and when the temperature is above 40 degrees Fahrenheit. Colder temperatures cause the pavement to contract, allowing the crack to expand and fill correctly. Traffic should be avoided on the sealed fractures until the sealant has dried.

How does crack sealing work?

It includes routing, a technique performed before cracks are sealed. Routing is done with a machine that extends the cracks to 14″ wide, creating a reservoir for the rubberized crack sealer to sit in. Workers wipe out the fissures to provide the best possible adhesion.

The above procedure guarantees that the rubber thoroughly penetrates the fracture and adheres to the existing pavement. In comparison to inserting rubber directly into existing, non-routed fractures, it helps establish a waterproof barrier to prevent leaks.

Other methods:

If the existing pavement has many fine cracks but is still structurally sound, you can apply a general bituminous surface treatment (BST) or slurry seal rather than filling each crack. It is a more cost-effective method.

Excessive crack sealing should be avoided. Other treatments, such as thicker overlays or milling, interlayer or surface treatments in combination with an overlay, may be more suited if the sealant quantity is larger than 5,000 lbs. per lane mile.

PowerSurge Plus LLC is a professional asphalt repair company in Philadelphia, PA; we provide timely and effective services to prevent pavement degradation from worsening, hence avoiding surface pavement breakdown and costly repairs.

Add A Basketball Court To Your Backyard

Do you spend your weekend playing ball with the kids in your driveway? Maybe you shoot some hoops to relieve stress after work. Or perhaps you’re struggling to stay active and get outside more. Whatever your level of interest, if you enjoy playing basketball or are looking for ways to maintain your physique, it’s worth considering building a court to your backyard.

Building a basketball court, like any other home improvement project, necessitates careful preparation. A sports court can add value to your property, but it also comes with certain maintenance considerations. Let’s look at the basic information you’ll need to construct a basketball court.

The Requirements:

Before starting the construction process, you’ll need to consider a few things. These factors will play a part in deducing the cost of your project.

A Level Surface:

Finding a level surface is the make-it-or-break-it factor for your home basketball court. You will first need to check the slope of your yard with a transit or laser level.

The ideal situation is to have a completely flat backyard, but that’s not always possible. If there is any slope, you’ll need to factor that into your budget for excavation and grading work.

Base Material:

Base material refers to the foundation that will support your court surface. The three most common materials used are concrete or concrete.

Using concrete is a more expensive option, but it will last longer and provide a better surface for your court. In contrast, asphalt is a less expensive option, but it will require more maintenance over time. Walking too much on an asphalt surface could lead to fading and cracks.

Performance Material:

The topmost layer of your court is referred to as the performance material. The material you use depends on the type of sports you will be playing on the court. For basketball, the most common materials are vinyl, sports tiles, and wood flooring. Each of these materials has different benefits.

Use high-quality performance materials in your best interest because they will last longer and provide a better surface for your court.

Cost of Building a Backyard Basketball Court:

A basketball court is one of the most commonly built sports courts homeowners add to their backyard. The cost of adding a basketball court to your backyard will depend on the size and type of court you want and the factors above.

Half-Court

A half-court is the way to go when you’re tight on space but still want to ball out. A small backyard can accommodate a half-court with ease and leave plenty of room for other activities. Half-courts typically cost between $12,500 and $35,000. You’ll be able to adjust only one basketball hoop on this court, which is not bad for a fun family game or shooting some hoops by yourself.

Junior-Court

Junior courts are smaller than full courts but still accommodate two hoops for a full-fledged game. These courts are perfect for your little champions. You can expect to pay between $36,000 and $46,000. If you have a little more space in your backyard but don’t want to spend too much, this is the perfect option.

Full-Court

As the name suggests, a full-court can fit an entire regulation basketball game. Of course, this requires a lot of space. If you have the space and the budget, go for it! A full court will cost you between $46,000 and $70,000.

Conclusion:

Adequate installation and maintenance of your backyard basketball court are crucial to get the most out of it and ensure its durability. You should always consult a professional to get perfect results.

PowerSurge Plus LLC, serving Levittown, PA, offers sports court surfacing services to maintain your investment look.

Have you ever wondered why pavement curbing is installed around roadways and sidewalks? Curbing serves an essential purpose in safety and functionality, but its origins date back much further than you may think.

In this blog post, PowerSurge Plus LLC will answer some of the questions that have been at the back of your mind for some time, like what are they for? And how did they become such an integral part of our neighborhoods?

Let’s take a closer look at pavement curbing and its history.

The History of Pavement Curbing:

Pavement curbing has a long and complicated history. It is believed to date back to 4000 BC in ancient Mesopotamia. Curbing was originally used to separate different areas within cities and protect against flooding.

Pavement Curbing Material History:

Curbing is typically made of concrete, stone, or asphalt. The first concrete curbs were installed in the late 1800s.

The material used for curbing has changed over time from stone to wood to concrete. In the United States, concrete became the standard material in the early 1900s because it was less expensive to install.

First Patent for a Concrete Pavement Curb:

The first patent for a concrete pavement curb was filed in 1911 by George Bartholomew of Detroit, MI. His design used a mold to create a consistent shape and size for the curb.

Bartholomew’s design was quickly adopted by cities across the United States and remains the standard today.

Purpose of Pavement Curbing:

Delineation Between Areas:

While the material and design of curbing have changed over time, its purpose has remained essentially the same: to delineate between areas.

Curbing is used to separate different types of pavements, like sidewalks from roadways. It also separates landscaped areas from areas of high foot traffic.

Acting as Barriers:

In addition to delineating different areas, curbing can also act as a barrier. Curbing is often used to prevent vehicles from driving onto sidewalks or landscaped areas.

It is used to provide pedestrian walkways that are separated from roadways. It helps to create a safe environment for pedestrians and motorists alike.

To Improve Aesthetic Appeal:

While functional, curbing can also be used to improve the aesthetic appeal of an area. Curbing can be used to create defined edges for landscaped areas.

It adds visual interest to pedestrian walkways and roadways. When done correctly, curbing can help give an area a polished and well-maintained look.

To Deter Erosion:

In some cases, curbing can be used to deter erosion. It is often seen in areas prone to flooding or where there is a lot of runoff. Curbing can help to redirect water flow and prevent soil erosion.

To Improve Safety:

One of the most critical functions of curbing is to improve safety. Curbing can be used to create separation between pedestrian walkways and roadways. It helps to prevent pedestrians from walking into traffic.

Curbing is an essential part of pavement maintenance, but it’s also a fascinating piece of history and engineering.

If you require curb installation or repair services in West Chester, PA, please get in touch with PowerSurge Plus LLC. We provide quality curb installation and repair services for businesses and homeowners alike. Get your free quote today!

The Essential Driveway Maintenance Checklist

Driveway maintenance is vital for the aesthetics of your home, but it’s also crucial for keeping your vehicle safe. A smooth surface will ensure that you don’t have to worry about getting stuck in a ditch or losing control while pulling out of your driveway.PowerSurge Plus LLC will provide you with a checklist of essential tasks that you can do yourself to keep your driveway looking great and functioning perfectly.

DIY Driveway Maintenance Checklist

If you have a concrete driveway, then you know that proper maintenance is essential to keeping it looking its best. But what exactly does proper maintenance entail? And how often does it need to be done? We’ve got you covered with this essential DIY driveway maintenance checklist. These easy tips will ensure your driveway stays in tip-top shape!

1. Clean Your Driveway

First on our list is to clean the driveway. It will help remove any built-up dirt or debris from the surface. Next, we recommend washing the driveway with a power washer to ensure further that all dirt and grime are removed. Pressure wash your asphalt surface at least once a year to remove any built-up dirt, oil, or grease. Once the driveway is clean, you’ll want to make sure that it is scorched before moving on to the next step.

2. Pack the Cracks

After the driveway is dry, you’ll need to pack any cracks that have developed. It can be done with a putty knife or unique concrete filler. If you live in an area with harsh winters, it’s crucial to take extra care of your driveway during the colder months.

3. Apply Acrylic Sealer

Once the cracks are filled, you’ll want to apply an acrylic sealer over the top. It will protect your driveway from future damage and weathering. Filling and Sealing the cracks will help prevent ice from forming in the gaps and causing further damage.

4. Topcoat with Acrylic Layer

Additionally, you should apply an acrylic topcoat to your driveway every few years to protect it from the elements. It will also give your driveway a smooth, finished look and shine.

With a little bit of annual maintenance, you can keep your driveway looking smooth and damage-free for years to come. So don’t wait – get started on your DIY driveway maintenance checklist today!

Ending Note

Keeping your driveway in good condition is vital for the safety and appearance of your home. By following our essential driveway maintenance checklist, you can DIY many tasks to make your surface smooth and look great. If you require any professional to help with some of the more complex jobs, get a quote from PowerSurge Plus LLC, serving Allentown, PA, today. We would be happy to assist you in maintaining your driveway so that it always looks its best!

Alligator cracking occurs when the subsurface of the pavement is not strong enough to support the weight of the traffic above. Several factors can cause it, including poor drainage, inadequate foundation, or simply too much traffic.

Alligator cracking typically appears as diagonal cracks that radiate outward from a central point. It can quickly lead to potholes and other forms of pavement failure.

It’s crucial to address alligator cracking as soon as it is noticed.

This blog post by Power Surge Plus LLC discusses why alligator cracking happens, how to prevent it, and how to repair it if it has already occurred.

Why Does Alligator Cracking Happen During The spring Specifically?

There are several reasons for this, but the most likely cause is the changes in temperature and moisture levels. The warmer temperatures and higher humidity levels of spring provide the perfect conditions for forming cracks. In addition, spring is when roads see the heaviest traffic as people take advantage of the good weather to travel.

The thawing process, also known as thaw weakening, starts in early spring when temperatures rise, and the snow melts. The base course might be weakened because of a severe spring thaw, similar to inadequate drainage, causing fatigue cracking. Also, the weight of vehicles on the roads can cause additional cracking. So if you live in an area prone to alligator cracking, be extra careful when driving during this time of year!

Of course, this is not to say that alligator cracking can never happen in other seasons.

How To Prevent Alligator Cracking From Happening In Your Driveway Or Parking Lot?

Over time, the surface can become uneven and cracked, creating a hazard for pedestrians and vehicles. Alligator cracking occurs when the surface layer of asphalt is damaged, leaving the underlying layers exposed.

The best way to prevent alligator cracking is to have the surface regularly professionally seal coated. This will help fill in cracks and prevent new ones from forming. In addition, seal coating will protect the surface from the sun’s UV rays and other weather damage. So, seal coating is essential for keeping your driveway or parking lot in good condition.

Repairing Or Replacing An Asphalt Driveway

Most asphalt driveways and parking lots will experience some cracking over time. This cracking is not typically a structural issue. It can be unsightly and cause water to pool on the asphalt surface.

There are a few different solutions for repairing or replacing an asphalt driveway or parking lot that has been affected by alligator cracking.

- Fill the cracks with a sealant or patching material.

- Another option is to remove the damaged section of asphalt and replace it with new asphalt.

- Finally, if the entire surface is cracked, it may be necessary to remove it.

Power Surge Plus LLC serving Cherry Hill, NJ, provides asphalt repair and patchwork. We provide crack sealing, crack filling, pothole repair, and infrared repair. Get your free quote now!

We all know that feeling. You’re playing on the court, and suddenly you notice a big, ugly blemish in the middle of the playing surface. It throws off your game and ruins your fun.

But before you go running up to the poor repair guy, have you ever considered striping it yourself? This blog post by PowerSurge Plus LLC briefs about line striping paints for sports courts. So if you’re looking to get your court back in tip-top shape, keep reading!

Why is Line Striping Essential for Sports Courts?

It’s essential to regularly repaint the lines to keep your sports court in tip-top shape. It creates a visual boundary for the playing area and increases safety by clearly defining boundaries. In addition, it can improve the overall appearance of the sports court.

Things to Consider:

When it comes to line striping paints for sports courts, there are a few things you need to consider.

Consider the Surface:

The first is the type of surface you’re working with. Asphalt and concrete surfaces are much harder than wood or other materials, so they require a different kind of paint.

If you have an asphalt surface, you’ll need to apply an asphalt paving and concrete excavation sealant first. Doing this will protect the surface from further damage and help to keep it looking new for longer.

If you have a concrete surface, you’ll need to apply a crack sealing and infrared patching compound to any cracks or holes before you start painting.

Consider the Durability:

The second consideration is the level of durability you need. If you’re playing a high-intensity sport like football or basketball, the last thing you want is for your court to start wearing down. That’s why durable line striping paint is essential.

Steps to follow when Renovating your Sports Court:

- Strip the old line markings off the court surface with a line striping paint.

- Apply an asphalt paving and concrete excavation sealant to protect the surface from further damage.

- Apply a crack sealing and infrared patching compound to any cracks in the surface.

- Spray or paint on new line markings in your desired color scheme.

- Finish off by applying an anti-skid coating to the surface.

Some Handy Tips for Line Striping Sports Courts:

Mentioned below are some of the things you should keep in mind when striping your sports court:

- Always follow the manufacturer’s instructions for the best results.

- Use a steady hand and be careful not to overfill or spill paint onto neighboring areas.

- Make sure that the court has dried completely before using it.

- Repeat the process every two to three years for optimal results.

Bottom Line:

Upgrading your sports court can give your community a much-needed boost in morale and encourage people of all ages to get active. With only a bit of elbow grease, you can have your sports court looking like new!

We’ve got just the thing if you require an excellent line striping paint for your sports court in Philadelphia, PA. Our asphalt and the commercial paving team at PowerSurge Plus LLC can help get the job done right. Plus, we offer concrete repair services to fix any cracks or damage that may have occurred.

Get your quote today and see how much money you can save!

Walk into any commercial parking lot, and you’ll be sure to see bollards. Those tall poles sticking out of the ground that separate parking spaces from sidewalks? While many people might take them for granted, these humble dividers play an essential role in keeping pedestrians safe.

Yet what happens when they start showing their age? Do you have to replace them all, or is there a way to refurbish them instead?

In this blog post, PowerSurge Plus LLC will explore the ins and outs of bollard maintenance and provide some tips on how to tell if your sidewalk bollards need an overhaul.

If you’ve noticed that your bollards (whether metal or concrete) are starting to show signs of wear and tear, it is time to think about replacing them. Here are a few warning signs that indicate it’s time for an upgrade:

Faded Paint

The paint is chipped or faded. At first, it wouldn’t seem like a problem but faded or chipped paint can quickly turn into rust. And once rust sets in, it’s only a matter of time before your bollards start to deteriorate.

Unstable Bollards

The bollards are starting to lean. It is a sure sign that the foundations are no longer stable and that the bollards could topple over.

Cracks inThe Concrete

There are cracks in the concrete or asphalt around the bollards. It means that the ground can no longer support the weight of the bollards, and they could sink into the ground if you don’t take action soon.

Serious Dents & Dings

The bollards have serious dents and dings. It could occur for several reasons, including bad weather, car accidents, or even intentional vandalism. Regardless of the cause, dented bollards can no longer do their job correctly and must be replaced.

Recurring Loose Fitting Issues

If the bollards constantly come loose, no matter how often you tighten them. It is a sign that the ground around the bollards has eroded and can no longer provide a tight fit. As a result, the bollards could come loose and cause damage or injuries.

Warping or Cracking

The bollards are warped or cracked. It is usually due to exposure to the elements, such as extreme heat or cold. Warped or cracked bollards are no longer stable and need to be replaced.

Missing Parts

The bollards are missing parts, such as the caps or reflective tape. It makes the bollards less visible and makes them more susceptible to damage. Missing parts also make it easier for people to remove the bollards, which could create a security risk.

Keep an eye on your bollards and make sure they’re in good condition. After all, they play an essential role in keeping your commercial district safe!

If you find that they need attention, don’t worry – we can help. Just call Power Surge Plus LLC, and we’ll schedule a service for you. Whether it’s the asphalt pavement maintenance, crack sealing, seal coating, or line striping, we are here in Levittown, PA, to help!