Key Takeaways:

- There are many asphalt crack fillers on the market, each with its specific purpose.

- Flex-A-Fill is product contractors use to fill in cracks and joints; it sets quickly and hardens quickly.

- Deery Hot Pour Rubberized Asphalt Crack Filler is our favorite because it saves contractors money on maintenance supplies and can fill cracks up to 1″ in width.

- Latex-ite Pli-Stix Blacktop Joint and Crack Filler come in long, thin sticks instead of huge blocks; application is easy – simply wedge it inside the cracks and melt it with a handheld torch.

- When choosing a good crack filler, look for one that is versatile, dries quickly, can withstand extreme temperatures, is non-tracking, and is easy to use.

Anyone who has ever dealt with a cracked driveway, sidewalk, or concrete surface knows that it can be a real headache to fix. The joyful news is that several products on the market are designed to make this process a little bit easier. So, which one is the best?

PowerSurge Plus LLC will look at three popular asphalt crack fillers and compare their features and benefits in this blog post. We’ll also discuss when each product is best suited for use. By the end of this article, you’ll have all the information you need to make an informed decision about which crack filler is suitable for your needs.

Asphalt Crack Fillers: A Brief Overview

The asphalt market is huge – The global market revenue for asphalt plants is predicted to reach nearly 2.5 billion U.S. dollars by 2027. Asphalt pavement owners everywhere rely on crack fillers to prevent costly repairs. Without crack filler, pavement cracks would expand and eventually turn into potholes. These potholes need to be repaired, which can be pretty expensive. In extreme cases, you may even have to repave the damaged area.

This is why crack fillers are so important. They act as a barrier, filling in the cracks and stopping water and other debris from seeping through. This protects the asphalt beneath, prolonging its lifespan. There are many different sorts of crack fillers on the market, each designed for specific purposes.

But with so many products on the market, how do you know the best? We checked out four different asphalt crack filler brands to see which one lasts longer, dries faster, and gives you more bang for your buck. Check it out below!

Flex-A-Fill Hot Asphalt Crack Filler

Contractors use Flex-A-Fill to fill cracks and joints. It sets quickly and hardens fast, so people can use the area as soon as the product is dry. One of its primary benefits is that it works for asphalt & concrete, making it convenient for contractors who work with both types of pavement. Additionally, it is versatile enough to fix roads, driveways, parking lots, and airport runways.

Unfortunately, this crack filler can only be used with a direct-fire melter. You’ll have to explore other options if you use an oil-jacketed crack fill melter.

Pros:

- Dries within an hour or two

- Inexpensive

- You can use it to repair asphalt and concrete

- Professional-grade crack filler

- This crack filler can cover up to 230 linear feet per block, making it ideal for filling in large cracks.

Cons:

- You can use it in direct-fire melters only

Deery Hot Pour Rubberized Crack Filler

The Deery Hot Pour Rubberized Asphalt Crack Filler is our favorite crack filler for many reasons: it saves contractors money on asphalt maintenance supplies. It can fill cracks up to 1″ in width in parking lots and driveways, which means less time spent working on a single job site. Plus, it dries and hardens in only an hour or two, so your crew can quickly move on to other Jobsite projects. It stays dark and firm even years from now – giving your customers real value for their investment.

Pros:

- It dries within an hour or two

- It is flexible yet firm and can last up to 4 years

- It’s Versatile — it can be applied using direct-fire and oil-jacketed melters

- The crack filler is 100% professional grade

- This product can cover up to 200 linear feet per block

- Use it to fill cracks in concrete and asphalt

Cons:

- The cost is higher compared to other brands

Latex-ite Pli-Stix Blacktop Joint and Crack Filler

One package will not be sufficient if you have many cracks to cover.

Latex-ite is quite a unique product; it comes in long, thin sticks as opposed to the huge 30-lb blocks in which the first two products come. Each pack can cover up to 30 feet of cracks (1/2″ to 1″ wide).

The application is straightforward – wedge it inside the cracks and melt it with a handheld torch. There is no need to remove the plastic wrapper; it melts along with the product.

However, this might not be the best product if you have deep and wide cracks that need repair. If you’re a contractor who needs to service multiple properties in one day, use hot pour crack fillers instead.

Pros:

- Contractors and do-it-yourselfers can use this product on asphalt and concrete.

- It can be applied using a handheld torch,

- One package can cover up to around 30 feet of cracks.

Cons:

- It takes a longer time to dry.

A Good Crack Filler: What to Look For?

1. Versatile

Your primary focus is asphalt repair and maintenance, but what if a customer requests you to fix cracks in concrete? In instances like that, it’s helpful to have a versatile crack-filling product. If you want to keep customers who ask for repairs on concrete surfaces, then it would be best to get a crack-filling product that can serve both purposes: asphalt and concrete.

2. Dries Quickly

You do not want to keep your customers waiting, so getting an asphalt crack filler that dries quickly is essential. No one likes dealing with a sticky surface, and slow-drying products usually cause this problem. Get a crack filler that dries in 30 minutes to save yourself from the hassle.

Also Read: Seal Coating In October: Yay Or Nay For Your Driveway?

3. Able to Withstand extreme temperatures

There will be times when you’ll have to work under extreme weather conditions. For example, summer temperatures can go up to 100 degrees Fahrenheit. In such cases, it’s important to use a crack filler that can withstand high temperatures without losing its properties.

4. Non-tracking

When repairing cracks, you don’t want the filler material to track onto your flooring or clothing. This can be a big issue, especially with products prone to dripping. Look for a non-tracking crack filler to avoid this issue.

5. Ease of use

Some crack fillers are easier to apply than others. If you’re not experienced in using these products, choosing one that’s easy to apply is best. Otherwise, folks might end up making a mess and wasting the product.

Bottom Line

These are some of the best asphalt crack fillers on the market. Be sure to choose one that’s best suited to your needs. And don’t forget to follow the manufacturer’s instructions when using the product.

Looking For Asphalt Repair In Bucks & Montgomery Counties, PA? Let Us Help!

PowerSurge Plus LLC is an asphalt maintenance & repair firm based in Bucks & Montgomery Counties, PA, that offers affordable, customer-oriented services intending to build long-term relationships with clients. Our experts are dedicated to providing high-quality asphalt crack repair services and satisfactory results that gain our client’s trust and loyalty. We are well aware of the importance of maintaining a safe and smooth driveway, parking lot, or road, which is why we only use the best materials for every repair.

We offer asphalt crack sealing, pothole repair, sealcoating, line striping, and more. We also provide free quotes! Contact us today.

Signage 101 – Standard Signage Sizes

Key Takeaways:

- 24″ x 36″ is the most popular size for signage and is perfect for storefronts, window displays, and indoor signage.

- A-frame signs will help you attract attention to your business as they can be placed on sidewalks or in front of your store.

- The correct signage can help your customers find your business and make a positive first impression.

- A sign installation contractor can help you make the best decision for your needs.

Signs are an essential facet of any business. They are the first line of communication with customers and can set the tone for the entire customer experience. It is necessary to use standard signage sizes to make sure your signage is effective. It ensures that your signs are legible and look professional to everyone.

Let’s discuss the different standard signage sizes and what each one is used for so that you can decide on the appropriate size for your signage and bollard installation needs.

Standard Signage Sizes

Poster Size: 24″ X 36″

24″ x 36″ is the most popular size for signage. It is large enough to be seen from a distance but doesn’t overwhelm your customers. This size is perfect for storefronts, window displays, and indoor signage.

Banner Size: 2′ X 4′

Banners are an excellent way to get your message across to the customers. They are often used for special events, sales, or promotions. They can be hung from ceilings, walls, or even on fences.

A-Frame Sign: 24″ X 18″

A-frame signs will help you attract attention to your business. They can be placed on sidewalks or in front of your store. A-frame signs are perfect for companies that have a lot of foot traffic.

Yard Sign: 18″ X 24″

Yard signs can be used for advertising your business to passersby. They can be placed in front of your store or your yard. Yard signs are generally best suited to promote special events or sales.

Ledger Sign: 11″ X 17″

The ledger sign is one of the smaller standard signage sizes, typically used for directional signage or informational signage in office buildings or schools. Ledger signs can be placed on walls or doors and are often used with other signage to provide clear wayfinding information.

Letter: 8.5″ X 11″

This standard size is for letterhead, envelopes, and other office documents. It’s also a standard size for signage in small businesses, especially those just starting.

Other Lesser-Known Signage Sizes

Retail Poster Sizes

The average retail poster size is 20″ by 28″. However, some retailers will go bigger with their posters. However, what’s more important is that you must keep your signage proportional to the storefront size.

Movie Poster Sizes

The standard movie poster size is 27″ x 40″. Movie posters are printed on thicker paper stock than ordinary paper and displayed outdoors. The signs are often plastered on walls or billboards as an advertisement for the upcoming film.

Commercial And Residential Signage Sizes

There is no definitive answer regarding signage size for commercial and residential properties. However, every signage installation contractor recommends using at least 6 inches of tall signage. This will ensure that your signage is visible from a distance.

However, if you want to get signage and bollard installation of a bigger size, remember to keep it proportionate to the size of your building.

Things To Consider Before Getting a Signage Installation

Size is not the only thing you should consider before getting signage installed. Here are a few other factors:

- The type of sign to be used – You should decide on the kind of sign that is right for your business. It ensures you get the most out of your signage and bollard installation.

- The purpose of the signage – What do you want your sign to achieve? It will help determine your sign’s size, shape, and location.

- Your budget – How much are you willing to spend on signage installation? It will help narrow down your choices and ensure you get the most out of your budget.

- The location of the sign – Where will your signage be located? It’s an essential consideration as it will affect your sign’s visibility.

Kinds Of Materials Used in Signage and Bollard Installation

Several materials are used in signage and bollard installation. These include:

- Metal – This is one of the most common materials used in signage. Metal signs are durable and can withstand the elements.

- Plastic – Plastic signs are lightweight and easy to install. They are also less expensive than metal signs.

- Glass – Glass signs are sleek and modern. They can be backlit for added visibility.

- Aluminum – Aluminum is a popular choice for signage as it is durable and weather resistant. It is also easy to install and light in weight.

- Wood – Wood is another option for signage. It is sturdy and can be painted or stained to match your business’s branding.

- Acrylic – Acrylic is a clear plastic that is often used for signage. It is lightweight and shatter-resistant.

- Vinyl – Vinyl is a durable, flexible material that can be printed on. It is often used for outdoor signage to withstand weather and sun damage.

Benefits Of Choosing the Right Signage Size

There are various benefits to selecting the right signage size. The correct signage can help customers find your business, advertise your products or services, and make a positive first impression.

The wrong signage can be confusing, unreadable, and even off-putting. It is essential to take the time to choose the right signage size for your business.

A sign installation contractor can help you select the right signage size for your business. They will also install your signage correctly, ensuring it is visible and legible.

Why Choose a Sign Installation Contractor?

A sign installation company has the experience and expertise to install your signage correctly. They will also consider the size, placement, and type of signage you need.

Hiring a sign installation contractor ensures that your signage is installed the first time correctly.

If you are still unsure what size or type of signage is right for your business, a sign installation contractor can help you make the best decision for your needs. They can provide expert advice and guidance on choosing the right signage size, type, and material for your project.

Are you looking also to install bollards on your commercial property? Here’s what you need to consider.

PowerSurge Plus LLC is a full-service residential and commercial company offering various services, including signage installation in Philadelphia, PA. We have been serving clients since 1998 and will help you realize the best options for your project. Get a quote today!

Key Takeaways

- The fall season is the right time to get ahead of your driveway maintenance needs.

- Seal coating is a common asphalt maintenance method that ensures your driveway stands the test of time.

- Seal coating just before winter ensures you can avoid snow from penetrating unwanted pesky cracks.

- Some experts, however, recommend avoiding seal coating during the fall and winter seasons.

- Whether you seal coat your driveway, you can extend its durability by following the necessary winter maintenance.

- Get help from professional experts for October driveway maintenance.

You know the drill:

- In the fall, the leaves start to change color.

- The air turns crisper.

- Pumpkin-flavored everything starts showing up on store shelves.

But what about your driveway?

Did you bother to schedule something in your driveway maintenance plans this fall? Or is the cracked & potholed pavement not reminder enough – or do you think the weather is too cold to pave? Should you seal coat it in October or wait until spring? Here’s what you need to know.

Did you bother to schedule something in your driveway maintenance plans this fall? Or is the cracked & potholed pavement not reminder enough – or do you think the weather is too cold to pave? Should you seal coat it in October or wait until spring? Here’s what you need to know.

What is Seal Coating?

Seal coating is a preventative maintenance treatment applied to asphalt pavement. It protects against water damage, UV rays, and oxidation. That is when oxygen molecules in the air interact with asphalt molecules, causing them to break down. This process makes asphalt brittle and more susceptible to cracking.

How is a Seal Coat Applied?

A seal coat is spread out with a brush or squeegee. First, a layer of gravel is leveled over the pavement to provide a good base for the seal coat material. Next, the seal coat material is mixed and then applied to the pavement in a thin layer. Once a coat has been applied, it needs to cure for 24-48 hours before it can be driven on.

Why October is the Ideal Month for A Seal Coat

October is ideal for a seal coat because the weather is cool and dry. This prevents the sealant from drying too quickly and ensures that it will adhere properly to the pavement’s surface. In addition, cooler temperatures help prolong the lifetime of the seal coat.

Seal coating in October also has the added benefit of preventing water damage. Water can cause serious damage to asphalt pavement, especially during winter, when freezing temperatures can cause cracks to widen. By seal coating in October, you can protect your pavement from water damage all winter long!

Why is Asphalt Seal coating Important Before Winter?

Asphalt seal coating is a process that helps protect your driveway from the elements and extends its lifespan. Winter weather can be tough on asphalt, causing it to crack and crumble. Seal coating provides a barrier against the snow and ice, preventing water from seeping in and causing damage. It also helps fill in any existing cracks and potholes, which can become more significant problems during winter. Applying a seal coat before winter sets in is a great way to keep your driveway looking good and prevent costly damage down the road.

October Seal coating Process –

Asphalt is made up of small stones, sand, and binders. The sun’s ultraviolet rays oxidize the binders, making them brittle. Due to traffic, water, and snow, the pavement becomes cracked and worn down over time. Asphalt seal coating protects your pavement from the elements and extends its life.

Preparation is key to a successful job. You need to clean the area before you start seal coating. Be sure to remove any loose debris, such as leaves and twigs. You also need to fill any cracks or potholes with an asphalt filler or patching compound. Once the area is thoroughly prepped, you can begin seal coating.

To apply the sealer, pour it into a squeegee or tank applicator designed for asphalt sealer. Start at one end of the driveway and work your way across in overlapping strokes. After the first coat has been applied, let it dry for four to six hours before applying a second coat.

Why Some Experts Are Against Asphalt Seal coating in October?

Many experts recommend seal coating your driveway in the springtime. But what if you didn’t get around to it then? Is it still worth doing it in October?

Temperature

The ideal temperature for seal coating is between 55 and 90 degrees Fahrenheit. In October, temperatures can start to dip below 60 degrees at night, which can impact the quality of the seal coat. As a result, the seal coat may not adhere properly to the asphalt surface, leaving your driveway vulnerable to water damage.

Rain

Another concern with seal coating in October is rain. If it rains within 24 hours of the seal coat being applied, it can cause the sealer to deteriorate and wash away. You’ll have to redo the entire process, which can be costly and time-consuming.

Allergies

If you have allergies, you may want to avoid being around while applying the seal coat. The fumes from the process can aggravate allergies and respiratory problems, especially in the dry autumn season.

Also, Read – The Basic Differences Between Asphalt Seal coating and Asphalt Paving

October Driveway Maintenance Checklist

While you might be focused on raking up leaves and cleaning the gutters, don’t forget about your driveway! October is the perfect time to give your driveway some TLC so that it’s in tip-top shape when the snow starts flying.

Fix Cracks and Potholes

Cracks and potholes are not only unsightly, but they can also lead to bigger problems down the road. That’s why it’s important to fill them in as soon as you see them. You can use a sealant or patching material from your local hardware store to do this yourself, or you can hire a professional.

Remove Any Growth

If you have any weeds or grass growing in cracks in your driveway, now is the time to remove them. Use a weed whacker or trowel to dig them out, then apply a weed killer to prevent them from coming back.

Sweeping and Cleaning

Lastly, be sure to sweep and clean your driveway regularly. This will help keep it free of debris and looking its best. Plus, it’s just good manners! (Your neighbors will thank you.)

Seal coating in October is a great way to protect your driveway from the cold weather and extend its life. If you live in an area that experiences below-freezing temperatures, seal coating in October can help prevent cracks and potholes from forming on your driveway. PowerSurge Plus LLC offers full-service residential and commercial maintenance in Cherry Hill, NJ, so be sure to get a free quote today!

Key Takeaways:

- Asphalt patching is not a one size fits all job. There are two types of patching: hot mix patching and cold mix patching.

- As the name suggests, cold patching is for cold temperature, and hot mix patching is, you guessed it, for hot temps.

- Cold asphalt patching is a quick fix, and hot mix patching is a more permanent solution.

- Cold patching is best for small cracks, and hot patching is best for bigger cracks.

- Both methods have their benefits & drawbacks as standard pavement repair techniques.

A well-kept stretch of asphalt is central to the appeal of a home’s driveway and a business’s parking lot. If that goes awry by a few degrees, one can make do with hot mix patching. But why is asphalt patching important in pavement maintenance? And how many types are there?

Potholes and cracks will eventually occur on asphalt-coated surfaces, resulting from extensive, ongoing damage and temperature changes. A good property requires monthly maintenance to stop future damage and lower the expense of asphalt repair. So whether it’s a parking lot or pavement, it is essential to restore asphalt as soon as the damage emerges.

Depending on the extent of the damage, restoration work may occasionally be as simple as patching up the area or need significant effort to restore the surface. There are several methods for repairing, with cold patches and hot mix being the most prevalent.

PowerSurge Plus LLC will discuss the differences between hot and cold patching and when each should be used in this blog post. We will also provide tips on properly doing both types of patching. So whether you are a business owner who needs to repair a driveway or a homeowner who wants to fix a pothole in your street, read on for all the information you need!

Hot Mix Asphalt Patching: The Basics

If you’ve ever passed a highway crew laying down fresh asphalt when it was steaming, it was hot mix asphalt being laid. As the name suggests, hot mix asphalt is a blend of aggregate, such as gravel and sand, and asphalt cement. The mixture needs heating before installation. At the manufacturing facility, hot mix asphalt is heated to a temperature of between 300 and 350 degrees before being delivered and laid at the intended project site. Since hot mix asphalt cools quickly, it reduces the installation time.

Benefits and Drawbacks of Hot Asphalt Patching:

Benefits:

- Cools down quickly: Since hot mix asphalt is installed at a high temperature, it cools down quickly. This means you can open up the area to traffic much sooner than cold patching.

- Stronger bond: Hot mix asphalt bonds better to the existing pavement because of the high temperatures. This results in a stronger, more durable repair.

- Weather-resistant: Asphalt is resistant to many kinds of weather, including wind, floods, and more.

- Durable: Hot mix asphalt is exceptionally durable, making it perfect for heavily used roads and highways. Cold mix asphalt is not sturdy enough to withstand normal vehicular usage.

- Flexible: Asphalt is flexible; it can bend but won’t break. The weather may cause it to contract and expand, but it won’t break or get damaged.

Drawbacks:

- Expensive: Hot mix asphalt is more expensive than cold patching because of the higher cost of materials and equipment.

- Requires specialized equipment: You need specialized equipment to heat and apply hot mix asphalt. This can be a costly investment for some contractors.

- Hot weather-sensitive: Hot mix asphalt can only be installed in hot weather. If the temperature drops below 38-40 degrees, the asphalt will not adhere to the surface and will not be set correctly.

When Is The Best Time To Use Hot Mix Patching?

Knowing the optimal circumstances to use hot mix asphalt is crucial. Hot mix patching is best done in hot weather, as the name suggests. A hot mix is a good option if you need to patch your asphalt quickly and don’t have enough time for the weather to warm up. It is also recommended for large-scale paving projects, such as roads, driveways, and parking lots. In Philadelphia, Pennsylvania, hot mix asphalt is a common choice for parking lots and roadways.

Cold Mix Asphalt Patching: The Basics

If you’ve ever seen a blacktop patch installed on your street or driveway, it was cold mix asphalt. Cold mix asphalt is made of a blend of aggregate and either emulsified asphalt or cutback asphalt. Unlike hot mix asphalt, which needs to be heated before installation, cold mix asphalt can be applied right out of the bag.

Benefits and Drawbacks of Cold Asphalt Patching:

Benefits:

- Affordability: Compared to hot mix asphalt, cold mix asphalt is significantly less expensive. Cold mix asphalt is more readily available, but hot mix asphalt calls for enormous volumes. Cold mix in single bags might be the best option for tiny areas without breaking the bank.

- No heating required: Since cold mix asphalt doesn’t require heat, it can be installed at any time of the year.

Drawbacks:

- Shorter lifespan: A hot mix asphalt driveway or parking lot will last 20-30 years. Cold mix asphalt will only last for about five years.

- Temporary: Since cold mix asphalt is only a temporary solution, it’s not ideal for high-traffic areas.

When Is The Best Time To Use Cold Patching?

Cold asphalt is a standard solution for filling up potholes or tiny gaps. Cold patch asphalt is the best option when the outside temperature is too low to utilize hot mix asphalt. Cold asphalt is often used for small-scale repairs like temporary patches until hot mix asphalt can be utilized for a more permanent repair since it is not as robust as hot mix asphalt.

Bottom Line:

Hot mix is the most acceptable option for patching up damage to an asphalt surface. It yields more effective and long-lasting benefits and saves money over time. It is a terrific method to maintain a property’s value. On the other hand, until hot mix patching is accessible, cold patching is an excellent temporary solution (or affordable).

PowerSurge Plus LLC can help!

As the leading pavement maintenance contractor in Philadelphia, PA, we specialize in all asphalt needs. We offer asphalt repair service to clear the surface area of any evidence of degradation.

Potholes, partial base failure, alligator cracking, and other significant damage are easily fixed with patching. Our experts remove the weaker asphalt to build a sturdy pavement and improve it with fresh asphalt. If you need a full teardown and ground-up pavement installation, then you know whom to call!

Tennis Court Resurfacing: The Dos And The Don’ts

Key Takeaways:

– Resurfacing your tennis court is an integral part of its maintenance.

– Make sure to hire a reputable contractor who uses high-quality materials

– Hiring a reputable asphalt contractor is key to tennis court resurfacing

– Tennis court resurfacing can prolong the life of your investment!

– High-quality materials are essential for tennis court resurfacing

– A few smaller steps can be taken to prevent tennis court resurfacing from being necessary often!

If you have a tennis or other sports court, you know that the surface begins to wear down and needs resurfacing or replacement with time. But what are the best options for sport court surfacing? And what are some of the Dos and Don’ts when it comes to maintaining your sports court?

At PowerSurge Plus LLC, we specialize in tennis court resurfacing and striping. We understand the challenges of having a tennis court or any other type of sports court in top shape. In this blog post, we’ll share top tips on maintaining your court well and some of the things you should avoid. Let’s begin.

Sports/Tennis Court Surfacing Explained

So what does it mean when we say surfacing or resurfacing of a tennis court? In short, it is applying a new top layer to an existing tennis court. Let’s look at some reasons why resurfacing becomes a necessity:

The current surface is beginning to show wear and tear

With time, your tennis court will start to show wear and tear. This is perfectly normal and expected with any court surface. However, suppose the deterioration is impacting the quality of your game. In that case, it might be the perfect time to consider resurfacing.

You want to change the type of surface.

Maybe you’re unhappy with how your current tennis court surface is playing. Or, perhaps you’re looking to change the type of surface altogether (e.g., from clay to hard court). In either case, resurfacing is the best way to achieve this.

The surface has been damaged.

In some cases, the tennis court surface itself can become damaged. The damage occurs due to severe weather conditions or careless use (e.g., parking a car on the court). If the damage is significant, resurfacing may be the only way to repair it.

The court is too old.

Even if the surface is in good condition, the underlying asphalt or concrete can degrade over time. This is especially true if the court wasn’t appropriately constructed in the first place. Resurfacing can help to extend the life of an old court.

The DOs:

Hire a professional company

Research different tennis court resurfacing companies and ask for quotes. You must be sure that the company you hire comes highly recommended and has a good reputation. Such a small, simple step can save you many headaches down the road.

Choose the correct type of surface.

The three most common tennis court surfaces are acrylic, clay, and grass. You must consider your region’s climate, playing style, and budget, each of which can contribute majorly to your sports court maintenance in the coming time.

Use high-quality materials

Some asphalt contractors in Levittown may use lower-quality materials to save money. However, sticking with a reputable and trusted contractor will save you from costly repairs down the line. The paradox is that, in the short term, it may seem like you’re spending more money. But you’ll be saving more if you look at the bigger picture.

Research in advance

Learn about all your potential options in tennis court resurfacing before making a decision. Discuss with your contractor what your specific needs are and what shall be your best course of action. The benefits and drawbacks of all resurfacing types should be considered before you’re ultimately ready to make a decision.

Prepare the surface

Before resurfacing occurs, the old surface needs to be removed entirely. This process is called “stripping” and is essential to create a smooth, even surface for the new layer. Failing to prepare the surface properly will cause the new resurfacing not to adhere correctly and could cause problems down the road.

Pay attention to detail.

Even the slightest imperfections can cause significant problems down the road. Make sure your asphalt contractor takes their time and pays attention to detail, especially in the freezing winters of Levittown, PA.

The DON’Ts:

Be frugal

It’s your tennis court we’re talking about, and you want it to last. Hiring a cheap, inexperienced contractor will only cost you more in the long run. We have seen many people who, in their wish to save money, hired someone who did a terrible job and then had to call us to fix it.

Forget about the base.

The base is the most crucial part of your sports court and should never be ignored. A well-constructed base will extend the life of your court and make resurfacing a breeze. Having a sturdy base helps maintain the maintenance, saving your space from unnecessary wear.

Wait too long

Tennis courts are like any other surface and need to be resurfaced every few years. The sooner you catch problems, the easier and cheaper they are to fix. In contrast, waiting too long will exacerbate the issues, making repairs more expensive and resurfacing a more daunting task.

Use the wrong products.

Not knowing what tennis court resurfacing products are available can be a costly mistake. Incorrectly using the wrong products on your court will only worsen any damage and make it more difficult (and expensive) to resurface later.

Ending Note:

Remember that resurfacing the tennis court is essential to keep your court looking and playing its best. Use the right products and trust the service of a reputable asphalt contractor to get the job done right.

Asphalt Contractor in Levittown, PA

A highly reputable asphalt contractor is critical in tennis court resurfacing. While not exceeding your budget, you want to ensure the job is done right to protect your investment. At PowerSurge Plus LLC, serving Levittown, PA, we specialize in sports court surfacing and striping, using only the highest quality materials. Our efficient team will ensure that your sports court maintains its charm and appeal for years to come!

Get a free quote today!

A bollard is a steel post that divides the road into discrete lanes for parking, traffic, and pedestrians. Automatic bollards block the way for security vehicles to enter a specific location that has been closed off to traffic at a given time.

You might have noticed automatic bollards being deployed on roadways or commercial buildings. Whatever the case, the property owners and area residents enjoy these cutting-edge devices’ benefits.

In this blog post, PowerSurge Plus LLC will discuss a few reasons why an automatic bollard system might be essential for your business.

Benefit 01: Automatic Bollards Enhance Traffic Control

The ability to regulate and control traffic flow is one of the automatic bollard system’s key benefits. Automatic bollards can block off certain areas or direct traffic to a specific lane. This is especially useful if you want to create separate lanes for parking, pedestrians, and vehicles.

Automatic bollards can also be used to create a barrier between a public area and a private area. For example, if you have a business that deals with sensitive information, you might want to consider installing an automatic bollard system to keep unauthorized people from entering the premises.

Benefit 02: Automatic Bollards Can Enhance the Aesthetics of Your Property

Another benefit of automatic bollards is that they can enhance the aesthetics of your property. Bollards come in a variety of materials, colors, and styles. You can choose bollards that match the architecture of your building or go for a more modern look. Automatic bollards can also create a unique and stylish design for your property.

Benefit 03: Automatic Bollards Are Easy To Install and Maintain

Automatic bollards are easy to install and low maintenance, so you won’t have to spend much on repairs and maintenance. Bollards can also be used in various applications, such as parking lots, driveways, sidewalks, etc.

Benefit 04: Automatic Bollards Can Increase the Safety of Your Property

Automatic bollards can also increase the safety of your property. Bollards can be used to create a physical barrier between pedestrians and vehicles. You can avoid accidents and injuries by installing them in your commercial area. Bollards can also be used to deter crime. They can make it more difficult for criminals to access your property, which can help to reduce the chances of theft or vandalism.

Benefit 05: Peace of Mind for the Owners

Last but not least, combining all the advantages above enables you to maximize the additional peace of mind your investment in automated bollards offers.

If the above benefits have persuaded you to install automatic bollards at your business, choose a professional contractor for the job.

PowerSurge Plus LLC provides expert installation services for bollards and signs in West Chester, PA.

We know exactly where (height and position) and how to install them to enhance usefulness because we are well-versed in the most recent industry practices (colors, materials, styles, etc.).

Asphalt paving and sealcoating might seem like the same thing to many people, but in reality, they are very different. Asphalt paving is a process that involves applying a layer of new asphalt to an existing surface. In contrast, asphalt sealcoating adds a protective layer to the asphalt surface.

This blog post will go over those differences and why they matter for your driveway or parking lot. So, if you’re curious about asphalt paving and seal coating, keep reading!

The Difference Between Asphalt Paving & Asphalt Sealcoating

While asphalt paving and sealcoating are sometimes used interchangeably, each has a distinct function.

Asphalt Paving

- This is a more permanent solution where a new layer of asphalt is laid over the existing surface. This process can be used to repair damaged areas or to add extra protection against wear and tear.

- Asphalt paving is used to repair or replace damaged or old asphalt driveways/ parking lots.

- It should be done every 5-7 years, depending on the severity of weather conditions in your area.

- Only professionals should do paving because it requires heavy equipment and experience.

Asphalt Sealcoating

- This is a process in which a protective layer of asphalt is applied to the pavement’s surface. This layer helps prevent water and UV damage and also inhibits the growth of weeds and other vegetation.

- It should be applied every 2-3 years, depending on the traffic the surface sees.

- Though amateurs can do sealcoating, we recommend hiring a professional for the best results.

- You may seal minor cracks or flaws with seal coating; however, seal coating may not cover major damage like potholes.

Paving vs. Sealcoating: Which Is Better for Me?

Asphalt paving is used for new construction projects or major repairs. This can be a great option if you’re looking to make a significant improvement to your property. However, it’s important to note that paving is a fairly invasive process. It can be disruptive and mess up your landscaping, so it’s not always the best option for minor repairs.

On the other hand, asphalt sealcoating is much less invasive. It involves applying a protective layer of asphalt over an existing surface. This can help prolong your pavement’s life and prevent damage from weathering, ultraviolet rays, and more. Seal coating is a great option for routine maintenance and small repairs.

So, when should you use asphalt paving & asphalt sealcoating? It depends on your needs and preferences. Paving may be the right choice if you’re looking for a major improvement. But sealcoating is probably the way to go if you’re looking to extend the life of your existing asphalt.

Power Surge Plus LLC is an asphalt paving company in Allentown, PA that offers premium asphalt paving and sealcoating solutions for residential & commercial surfaces. They provide expert services and guidance based on the project’s urgency, budget (or funds available), and local weather conditions.

Our services are fairly priced; get your free estimate now!

Concrete is a durable material, but it is not immune to damage. One common problem that can occur with concrete is cracking. There are many types of cracks, each with a different flaw trigger. If you know how to detect and repair the cracks, you can keep your concrete looking flawless and prevent further damage to the curb appeal!

PowerSurge Plus LLC will discuss the four most common concrete cracks and what they mean. We’ll also provide tips for the crack filling to repair the damage.

1. Shrinkage Cracks

Concrete is indestructible, but only if it is installed well. As it cures, it needs a degree of hydration to set; with uneven surface temperatures disrupting the curing, the concrete forms shrinkage cracks as it dries. They are usually small and only run through the top layer of concrete. They’re not typically a structural concern but can be unsightly with repeated freeze-thaw cycles.

Use caulk or asphalt sealant for crack filling to repair smaller gaps. You may need to use an asphalt or concrete patching compound for significant damage – but only over concrete surfaces.

2. Settlement Cracks

Soil stability & grading ensures evenly compacted surfaces to pave over. When shady contractors skip this step, or the land is naturally prone to geologic shifts, the soil can subside or shift over time. The paved concrete surface on the top also shifts and cracks.

It can also happen for various reasons, including poor drainage, erosion, or tree roots growing underneath the slab. These cracks are usually larger than shrinkage cracks and can be a structural concern.

You’ll need first to stabilize the ground underneath the slab to repair a settlement crack. It can be done by installing drainage around the perimeter of the concrete or by injecting polyurethane grout into the soil underneath the slab. Once the ground is stabilized, crack filling is done with asphalt sealant or concrete patching compound.

4. Expansion Cracks

These cracks occur when the concrete expands and contracts due to temperature changes without any allowance for expansion joints. These cracks are usually small and only run through the top layer of concrete. Use caulk or sealant for crack filling to repair the damage. You may need to use a patching compound if the crack is large.

If the damage is extensive, then a replacement patch & saw cuts as expansion joints are ideal for releasing the stresses in the pavement.

4. Heaving Cracks

When concrete is paved over moist soils in usually temperate climates, the temperature shifts can cause the soil to experience freeze-thaw cycles. The moisture in the soil expands as the water freezes and then subsides during the day. The gradual shifting can crack entire concrete slabs over time.

Ideal solutions are to repave or replace the slab and then apply a sealer.

Ending Note

If you’re seeing any of these five common concrete cracks in your driveway, patio, or sidewalk, don’t panic. With the proper knowledge and repair techniques, you can fix them and prevent further damage.

PowerSurge Plus LLC, serving Cherry Hill, NJ, is here to help. We’ll discuss each type of crack in detail and provide tips on how to fill and repair them. We offer free estimates for our concrete paving services to help you know what it will cost to get your concrete as good as new again. Contact us today to get started!

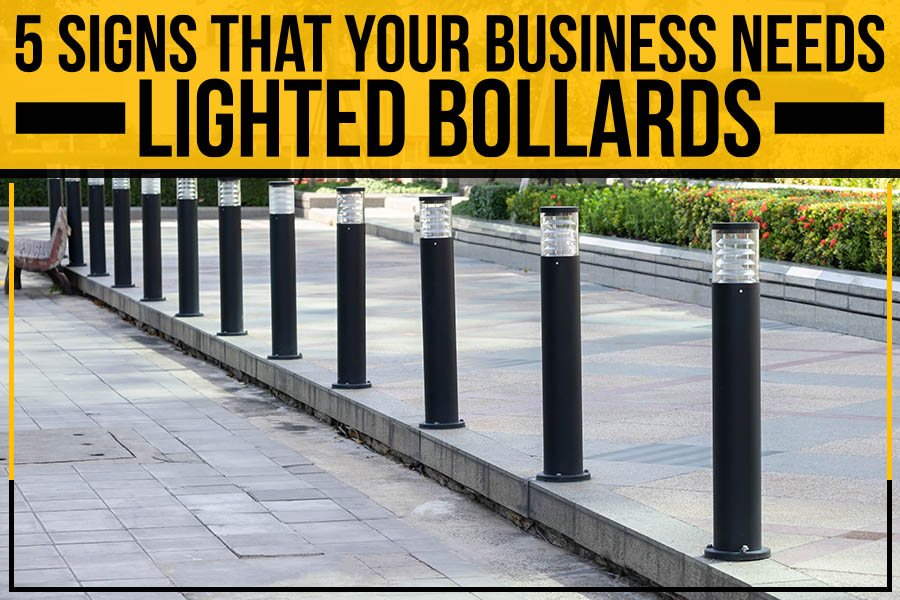

5 Signs That Your Business Needs Lighted Bollards

It’s no secret that businesses must take safety precautions to protect their customers, employees, and property. One such precaution is installing lighted bollards. Lighted bollards can provide a visual warning to pedestrians and drivers, directing them away from dangerous or off-limits areas.

In this blog post by PowerSurge Plus LLC, we’ll discuss lighted bollards in detail!

What Are Lighted Bollards?

Lighted bollards are posts installed in the ground around a property. They are typically made of concrete, metal, or plastic and can be either permanent or temporary. Bollards can mark a property’s boundaries, create a barrier around a building, or direct traffic flow. Many commercial establishments choose to install lighted bollards because they provide an extra level of safety and security.

There are many different types of lighted bollards available on the market. You can choose from solar-powered bollards, LED bollards, or even bollards with built-in security cameras. The type of bollard you choose will depend on your specific needs and budget.

Signs that Your Business Needs Lighted Bollards

If you’re not sure whether your business could benefit from lighted bollards, here are a few signs that they might be a good investment:

1. You Have a Lot of Pedestrians on Your Property

Protecting pedestrians from hazards is essential if your business is located where there is a lot of foot traffic. Lighted bollards can be used to provide a safe walking path for pedestrians and to direct them away from areas that are off-limits or dangerous.

2. You Have Vehicles on Your Property

If you have several vehicles on your property, it’s crucial to take measures to protect them from damage or theft. Lighted bollards can be used to create a physical barrier between vehicles and potential hazards. They can also deter drivers from parking in areas that may lead to damage or block pedestrian walkways.

3. You Want to Deter Crime

No business is immune to crime, but there are steps you can take to deter would-be criminals from targeting your property. Lighted bollards can make it more difficult for criminals to access your property after hours.

4. You Have Increased Traffic

If you have recently experienced an increase in traffic, it is important to ensure everyone is safe. Installing lighted bollards can help direct traffic and keep pedestrians and drivers safe.

5. You Want to Add to the Aesthetics of Your Property

In addition to their functional benefits, lighted bollards can also improve the aesthetics of your property. They can provide a touch of class and sophistication while also providing a measure of safety and security.

Conclusion

Bollards are a great way to improve safety and security, and they can be customized to meet the specific needs of your business. They have been proven to be very useful for businesses.

You need to contact an experienced company to discuss your options if you’re considering installing lighted bollards at your business.

When it comes to reliable lighted bollard installation, PowerSurge Plus LLC is perfect for the job. We serve Philadelphia, PA, and take pride in our expertise in Bollard/ Bumper Blocks & Sign Installation at affordable rates. We take customer satisfaction very seriously and work every day to improve our services!

Asphalt Maintenance & Repair: 3 Do’s And Don’ts

Asphalt is a common material for driveways and parking lots because it is durable, easy to maintain, and looks good. However, asphalt requires regular maintenance to maintain good condition and prevent costly repairs.

In this blog post, PowerSurge Plus LLC will discuss some dos and don’ts of asphalt maintenance and repair. Follow these tips to keep your asphalt looking great and lasting for years!

Don’t: Allow Heavy Equipment.

Heavy equipment can also damage your asphalt. If you have construction projects or large deliveries, notify your asphalt contractor. They can take measures to protect your pavement and minimize the impact of heavy equipment.

If you must have large trucks on your asphalt, you might choose to add a concrete pad where they frequently go.

Do: Drive with Care

Driving with care is one of the best ways to extend the lifespan of your asphalt. Avoid excessive speed, hard braking, and sharp turns. These activities can damage the surface of your pavement and lead to cracks and potholes.

Don’t: Forget to sweep your asphalt driveway at least once a year.

Sweeping your asphalt improves the look of the surface by removing loose particles. You may also check your asphalt for depressions and fractures that can point to early pavement deterioration. You may take preventative measures like crack filling and seal coating as soon as you notice symptoms of deterioration.

Do: Keep Up on Maintenance

It’s crucial to maintain your asphalt regularly. This includes crack filling and seal coating. Crack filling is essential because it prevents water from seeping into the cracks and causing damage. Sealcoating your asphalt every three to five years will help protect it from the sun and weather damage.

Don’t: Use Sprinklers.

While it might seem like a good and easy option to use sprinklers to keep your asphalt clean, it is damaging. If water seeps into your pavement, the base course will weaken, resulting in depressions that eventually become potholes.

Do: Pick the Right Contractor

Do your homework before choosing a contractor for asphalt maintenance or repair. Get multiple bids and read reviews. Ask about their experience and what type of asphalt they will use. The cheapest offer is not always a good option. You want to ensure you are getting a quality job that will last.

Hiring a professional asphalt contractor is the best way to ensure your asphalt is properly maintained and repaired. They have the experience and knowledge to do the job right.

When it comes to asphalt maintenance and repair, following these dos and don’ts will help extend the life of your pavement. Doing these things will also save you money in the long run and keep your asphalt looking great for years to come.

Want commercial or residential asphalt maintenance and repair?

Don’t worry! We handle asphalt projects at PowerSurge Plus LLC in Montgomeryville, PA. We provide competitive maintenance services utilizing the most effective methods to reduce downtime and inconvenience.

Our experts will assist you and demonstrate the level of attention and quality work we offer.